If you’ve spent time researching candle containers, you may have come across questions—or even concerns—about soda-lime glass. Occasionally, we hear from customers who wonder whether soda-lime glass is a negative or lower-quality material.

The short answer: it’s not.

In fact, soda-lime glass is one of the most widely used and trusted glass types in commercial manufacturing, and we choose it intentionally. Below, we’ll explain what soda-lime glass is, why it performs well for candle containers, and how our testing and quality processes ensure it meets the expectations of professional candle manufacturers.

What Is Soda-Lime Glass?

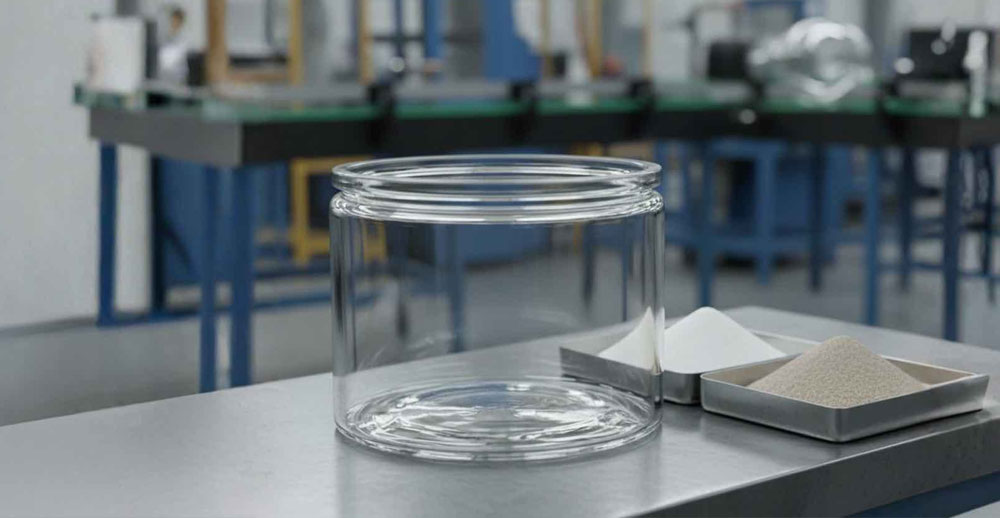

Soda-lime glass is the most common type of glass used worldwide. It’s made from a blend of silica (sand), soda ash, and limestone, which together create a durable, stable, and versatile material.

Because of its consistency and reliability, soda-lime glass is used across many industries, including food, beverage, home goods, and personal care packaging. Its widespread adoption isn’t accidental—it’s the result of decades of proven performance in commercial applications.

How Soda-Lime Glass Performs for Candle Containers

When it comes to candles, performance isn’t about the name of the material alone—it’s about testing, process, and consistency.

Tested to ASTM Standards

Our candle containers are tested in accordance with ASTM standards for candle use. These standards exist to evaluate safety and performance when glass is used in candle applications, including exposure to heat.

ASTM testing provides an established, industry-recognized framework to help ensure that containers perform as expected under candle-burning conditions. Meeting these standards is a foundational requirement for responsible candle container suppliers.

Additional Quality Checks Through the Finishing Process

Beyond ASTM-standard testing, our containers go through additional steps during production that contribute to consistency and durability.

Many of our containers are produced as clear glass and then painted. After painting, the containers undergo a baking process where they are reheated to cure the coating and then cooled again. This added thermal cycle acts as another layer of validation, helping ensure the finished container maintains its integrity and meets performance expectations.

This process is not unique to candles—it’s a quality-focused approach used in multiple industries where finished glass must perform reliably after additional treatments.

Addressing the “Cost-Effective” Misconception

One of the most common misunderstandings about soda-lime glass is that being cost-effective means it’s lower quality. In reality, cost efficiency is often the result of refined manufacturing processes, material availability, and scalability, not shortcuts.

Soda-lime glass offers:

- Consistent wall thickness and form

- Reliable performance across large production runs

- Broad availability that supports steady supply

- Excellent value without compromising quality standards

For candle manufacturers, this balance matters. It allows brands to maintain product quality, manage costs, and scale with confidence—without sacrificing safety or presentation.

Proven in the Market, Not Just on Paper

Glassnow has been supplying glass containers for over 30 years. During that time, soda-lime glass candle jars have been used successfully across countless production runs and brands.

Our confidence in this material doesn’t come from theory alone—it’s based on long-term market use, real-world performance, and ongoing quality evaluation. When questions arise, we’re able to stand behind our containers with both testing documentation and decades of experience.

Why Soda-Lime Glass Makes Sense for Many Candle Brands

While no single material is right for every application, soda-lime glass is a practical, proven choice for many candle manufacturers—especially those focused on consistency, scalability, and value.

It’s a material that performs well when paired with proper testing, thoughtful processes, and responsible manufacturing standards—which is exactly how we approach our container offerings.

A Thoughtful Choice, Backed by Standards and Experience

Soda-lime glass isn’t a compromise—it’s a deliberate choice rooted in performance, industry standards, and long-term reliability. When tested to ASTM standards and supported by consistent production processes, it delivers exactly what candle manufacturers need: safety, quality, and dependable results.

If you ever have questions about glass types, testing standards, or container performance, our team is always happy to provide clarity and documentation. Transparency is part of how we’ve built trust for more than three decades – email Sales@Glassnow.com or call 512.339.7808 and we’re here to help.